Product details

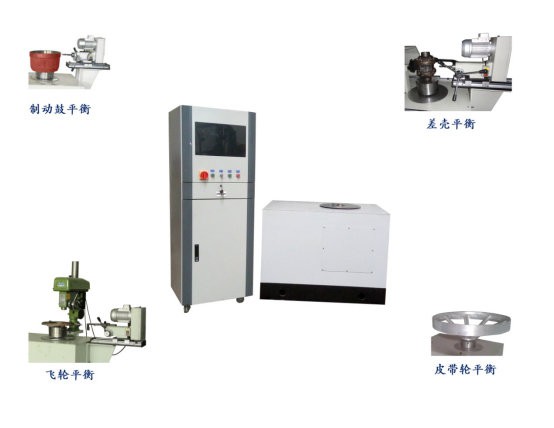

1. Introduction of YLD series products

This series is a single side vertical dynamic balancing machine, the conventional model measurement range of 200 kg, or according to the customer's needs can be customized within 5,000 kg of the single side vertical balancing machine. This machine is suitable for the check of the balance of the movement of the disc rotating parts on one side, it is an ideal equipment for the check of the balance of the movement of the fan blade, ventilator blade, automobile flywheel, clutch, brake disc, brake hub, hydraulic coupling and other parts. The series of conventional products are divided into "A" type and "Q" type. "A" type for frequency converter speed regulation, manual clamping workpiece; Q "type for variable frequency speed pneumatic clamping workpiece. Industrial control computer for data processing, color screen real-time display of unbalanced value, phase Angle and real-time speed, and equipped with industrial cabinet, and mechanical parts of the balance machine system, easy to save parameters, printing, high precision system test, reliable use, easy maintenance, more advanced than other test systems. And according to the customer's workpiece for the customer to customize a variety of general fixture or special fixture, also can be equipped with side to remove the weight of the drilling machine, set up to remove the weight of the drilling machine and vacuum equipment.

2. Measurement system

Industrial control computer, 19 "LCD display (can be customized with touch screen), Windows operating platform

★ within 200 kg vertical balance machine with the company's independent development of general balance measurement system. General software functions cover all the functions of the domestic mainstream balancing machine software, the operation of all the use of Chinese menu structure, operating steps text prompt; Large vertical balancing machine with Angle and tracking function of the vertical machine software

★ measuring system performance is strong: arbitrary workpiece calibration, measuring speed range wide 80 RPM starting, measuring speed block, unbalance amplitude and phase stability, high deweighting rate, high sensitivity

★ software with allowable unbalance calculator, the operator only needs to input the allowable vibration of the workpiece precision level, mass, working speed, and radius click to calculate the number of grams to allow the remaining unbalance of the workpiece

★ software completely independent development, according to customer requirements to modify or add software functions (such as scanning the two-dimensional code to add the workpiece identity name to the measurement results to save for future quality investigation)

Please contact the manufacturer for details of the software functions

3. Mechanical parts and controls

★ the equipment USES casting base, vertical support, spindle and support, the equipment has enough rigidity and stability, the same type of equipment overload capacity of more than 20 percent

★ spindle using 45# carbon structure steel, after forging, quenching, fine grinding, axial and radial runout are within 0.02mm; Even if the workpiece's unbalance exceeds 30000g*cm, the equipment can measure it accurately

★ power transmission adopts multi-wedge belt, stable and reliable transmission, small impact on balance measurement

★ spindle belt synchronous rotation dial, easy to find the uneven measurement Angle

★ the spindle is hollow structure, the spindle can be connected to the lower end of the rotary cylinder, through the pull rod and pneumatic chuck (or pneumatic tooling) can quickly clamp the workpiece

★ reliable quality of equipment, the use of frequency conversion speed control system, motor soft start soft stop on the impact of the equipment is small, extended the service life of the equipment. Equipment can work continuously, maintenance is simple and convenient

Note: please contact us for more information about the equipment

Manufacturer standard configuration parameters

Device model ldl-5 ldl-16a

The workpiece quality range is kg 0.1-5 0.3-16

Workpiece diameter Φ 500 Φ 500 mm

Equilibrium speed r/min 100-900 100-900

Minimum residual unbalance ≤1.5 GMM /kg ≤1.5 GMM /kg

Unbalance reduction rate % ≥95% ≥95%

Motor power 1.1kw 1.1kw

Clamping device clamping method manual clamping

★ the above is the factory standard configuration equipment parameters. We support product determination, according to the needs of customers for the equipment structure of the corresponding equipment allowed to change; For example, servo motor can be used to achieve automatic positioning function

★ if necessary equipment can be matched with electrical appliances for single-phase AC220V, 50/60hz power supply

★ the manufacturer provides the workpiece in the balance machine balance when the use of customized services

★ equipment can be added without affecting the measurement performance of reasonable accessories, such as protection, vertical or horizontal weight removal drilling machine