Product details

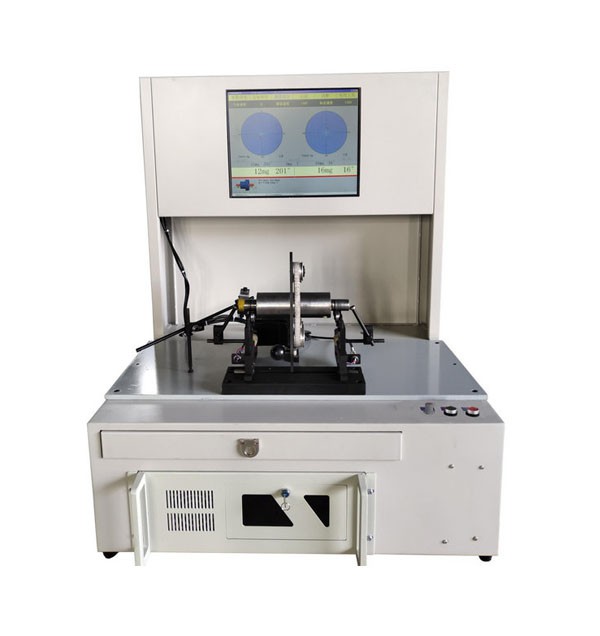

1. YYQ series product introduction

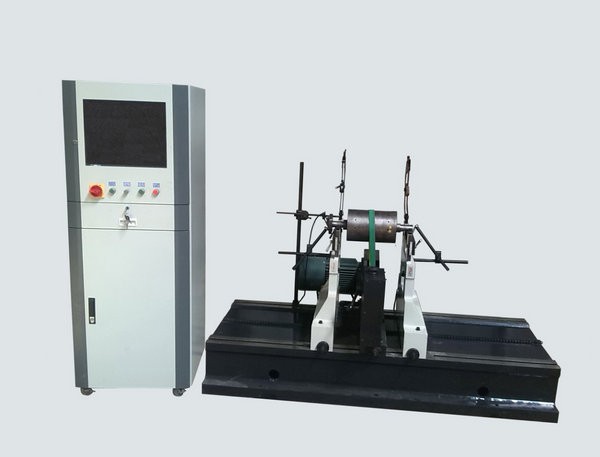

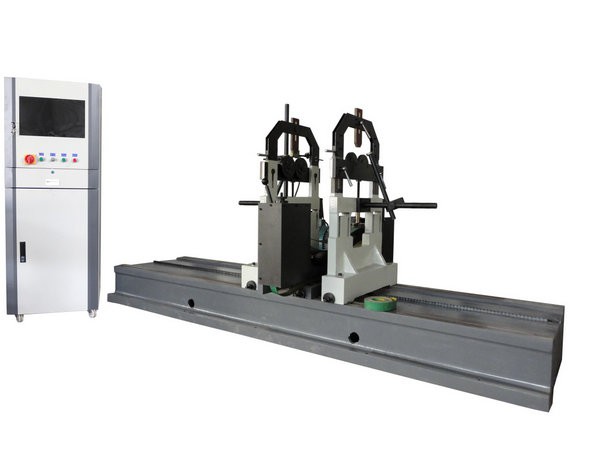

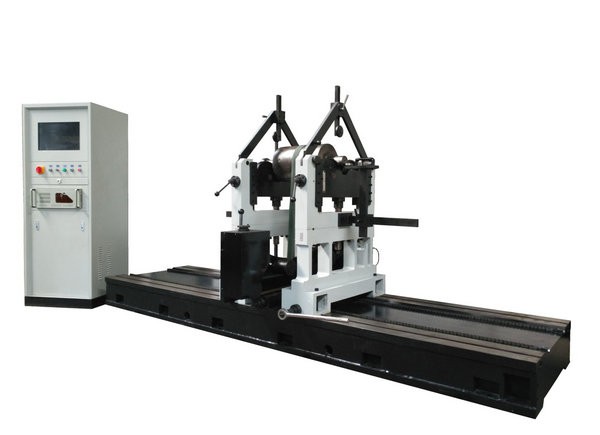

YYQ series is the belt drive drive universal hard support horizontal double-sided dynamic balancing machine, so the model comprehensive measurement range from tens of grams to 10000 kg. Suitable for balancing the motor rotor, roller (either with or without shaft head but without shaft head bigger diameter roller need to customize the institutions), shaft, machine tool spindle rules such as cylindrical rotor balance, balance above kinds parts without tooling, installation fast and convenient equipment measuring accuracy, higher precision is balanced with a universal joint machine; With the suitable jig can also balance the fan, pulley and other parts. Products are widely used in motor, generator, fan, engine, agricultural machinery, textile machinery, chemical, woodworking machinery, papermaking machinery and other industries, can be on one side, two sides and a number of correction surface balance measurement, suitable for shaft, disc type overhanging rotor. The advantages of accurate precision, intuitive display and reliable quality.

2. Measurement system

Industrial control computer, 19 "LCD display (can be customized with touch screen), Windows operating platform

★ with the company's independent development of balance measurement system. General software functions cover all the functions of the domestic mainstream balancing machine software, the operation of all the use of Chinese menu structure, operating steps text prompt; Special software includes: all kinds of automatic balancing machine software, with the function of tracking the Angle of the software, with the function of automatic positioning software, transmission shaft multi-axis joint school software

★ measuring system performance is strong: arbitrary workpiece calibration, measuring speed range wide 80 RPM starting, measuring speed block, unbalance amplitude and phase stability, high deweighting rate and separation ratio, high sensitivity

★ software with allowable unbalance calculator, the operator only needs to input the allowable vibration of the workpiece precision level, mass, working speed, and radius click to calculate the number of grams to allow the remaining unbalance of the workpiece

★ software completely independent development, according to customer requirements to modify or add software functions (such as scanning the two-dimensional code to add the workpiece identity name to the measurement results to save for future quality investigation)

3. Mechanical parts and controls

★ the body of the casting, enough rigidity and stability; Swing drive whole pair of line cutting and processing, anti-static pressure ability is strong, under the premise of sufficient device driving ability can overload more than 20 percent

★ the roller on the balance machine is made of bearing steel, the overall salt bath quenching hardness reached HRC55 above; After grinding the support surface of the roller, the radial runout of the polishing is small, and the roller bearing is arranged to make the workpiece run more smoothly and the interference to the measurement signal is lower

★ swing frame can move along the bed and can be parked in any part of the bed above, so the device can balance between arbitrary length of the workpiece.

★ the belt drive assembly can also be moved along the bed, convenient to drag the appropriate parts according to the workpiece.

★ reliable quality of equipment, the use of frequency conversion speed control system, motor soft start soft stop on the impact of the equipment is small, extended the service life of the equipment. Equipment can work continuously, maintenance is simple and convenient

Note: please contact us for more information about the equipment

Manufacturer standard configuration parameters

Device model yyq-30a

The mass range of workpiece is 0.5-30 kg

Circle with dragging diameter mm 30-300

The maximum diameter of the workpiece is mm 800

Support spacing mm 100-700

Length of bed mm 860

Roller support shaft diameter mm 10-80

300-1450 stepless speed regulation when the balanced speed r/min drag is 90mm in diameter

Minimum residual unbalance ≤0.5 GMM /kg

Unbalance reduction rate % ≥90%

Motor power 0.75kw

Speed regulation by frequency conversion

Operating voltage three-phase four-wire AC 380V, 50/60hz

★ the above is the factory's standard configuration equipment parameters, we support the product, system according to the customer's demand on the diameter of the equipment, the length, the roller support workpiece shaft diameter range to do equipment structure allows reasonable changes

★ if necessary equipment can be matched with electrical appliances for single-phase AC220V, 50/60hz power supply

★ the device can increase the Angle with the tracer function

★ equipment can be added without affecting the measurement of performance of reasonable accessories, such as protection and weight removal device