Product details

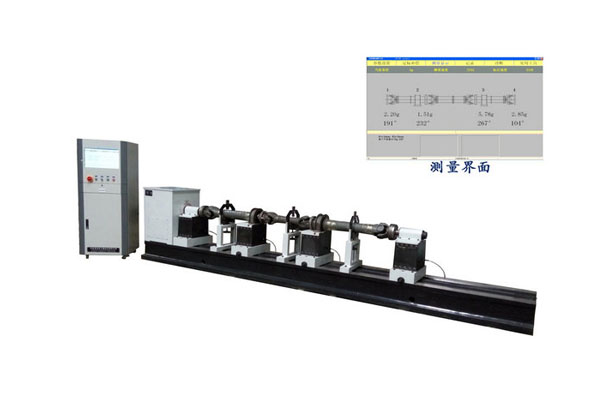

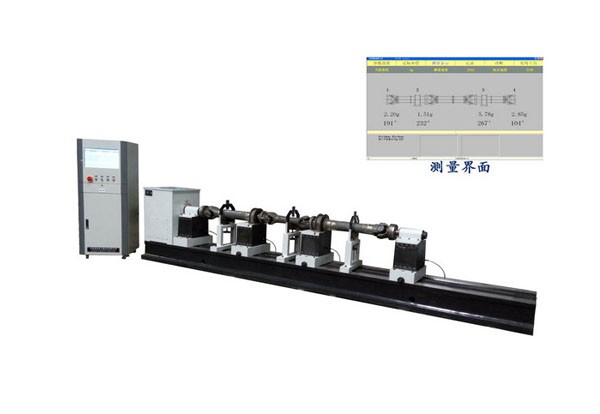

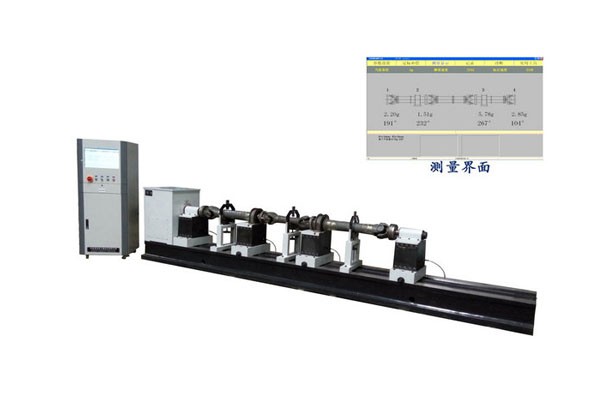

1. Introduction of the three-axis joint alignment drive shaft balancing machine

The three - axis joint - school drive shaft balancing machine is a special balancing machine, is specially used for the car drive shaft balance check the ideal equipment, only need to replace the fixture of the installation of the workpiece can do a variety of drive shaft dynamic balance correction. The equipment can not only conduct joint correction of three transmission shafts, but also uniaxial correction and joint correction of two transmission shafts. The swing frame adopts soft support structure, which is suitable for measuring the unbalance of the transmission shaft at high speed, and the measuring effect of the equipment is better.

2. Measurement system

Industrial control computer, 19 "LCD display (can be customized with touch screen), Windows operating platform

★ with the company's independent development of the transmission shaft balance special software, the software can choose a single section, 2, 3 sections of the transmission shaft correction way; The operation all USES the Chinese menu structure, the operation step text prompt

★ measurement system performance is strong: arbitrary workpiece calibration, vibration signal display, multiple correction surface unbalance display at the same time

★ software with allowable unbalance calculator, the operator only needs to input the allowable vibration of the workpiece precision level, mass, working speed, and radius click to calculate the number of grams to allow the remaining unbalance of the workpiece

★ software completely independent development, according to customer requirements to modify or add software functions (such as scanning the two-dimensional code to add the workpiece identity name to the measurement results to save for future quality investigation)

3. Mechanical parts and controls

★ soft support swing driving and casting bed, equipment stability is better, can be higher speed measurement shaft unbalance

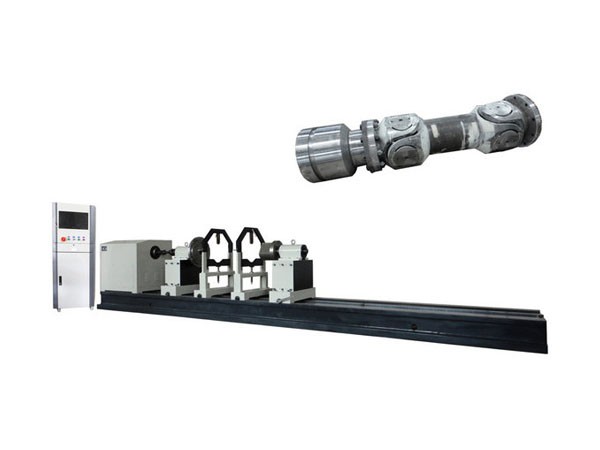

★ balance machine before and after the spindle structure, in the middle of the bridge for the two swing drive. The front and rear spindle flange has symmetrical long groove, the general stop can be matched with different sizes of positioning ring, the applicability of the equipment is stronger; When the transmission shaft is in the middle of the two suspension orchids are installed on the two bridge swing drive, when the two axis in the middle of the bridge swing drive is installed on the left side of the bridge swing drive, single section correction without the middle swing drive

★ swing frame can move along the bed and can be parked in any part of the bed above, so the device can balance between arbitrary length of the workpiece.

★ installation of synchronous rotation scale identification, easy to find the uneven measurement Angle.

★ photoelectric sensor measuring speed for high-speed measurement, magnetoelectric sensor measuring vibration for soft support structure

★ the use of variable frequency speed control system, according to the need to adjust the equipment motor start time is convenient to use

Note: please contact us for more information about the equipment

Manufacturer standard configuration parameters

Equipment model YDW - 300 - a Ⅱ

The maximum weight of the shaft is kg 100

Transmission shaft correction mode single - sided, two - sided, three - sided or four - sided correction

The maximum length of the workpiece is mm 3000

The length of the bed is mm 4500

Equilibrium speed r/min 500-3000

Minimum residual unbalance ≤20gmm/kg

Unbalance reduction rate % ≥85%

Motor power 3Kw

★ the above is the factory standard configuration equipment parameters, we support the product, system according to the customer's demand on the length of the equipment extension

★ according to the needs of the customer can customize the transmission shaft balance and equipment connected to the fixture

★ the equipment can be installed according to customer's requirements